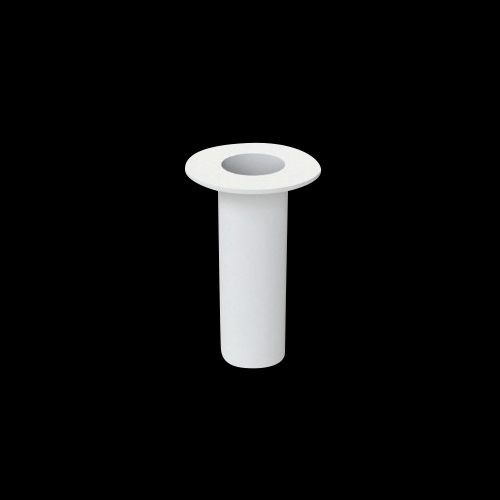

Fluoropolymer And PTFE Lined Closed Dip Pipe

Product Details:

Fluoropolymer And PTFE Lined Closed Dip Pipe Price And Quantity

- 50 Piece

Fluoropolymer And PTFE Lined Closed Dip Pipe Trade Information

- Cash in Advance (CID)

- 5000 Piece Per Month

- 2-10 Days

- All India

Product Description

The Fluoropolymer and PTFE Lined Closed Dip Pipe is the perfect solution for your chemical processing needs. The pipe is coated with a white surface treatment that not only looks great but also provides a layer of protection against corrosion and wear and tear. The round shape of the pipe ensures that it is easy to install and maintain, and the lining made of high-quality Fluoropolymer and PTFE materials makes it highly resistant to chemical reactions and high temperatures. The casting process used in manufacturing ensures that the product is of the highest quality and durability. With a warranty of 18 months, you can be sure that this product will last you a long time.

Specification

- ASME/ANSI B16.5 Class 150

- NB 1/2" to NB 8"

- Carbon Steel Body

- Standard Version: Straight Dip Pipe

Material

- Pipe: ASTM A 106 Gr. B

- Flanges: IS 2062 Plates/ASTM A 105

- Liner: ASTM D 1457

Available on request

- Angular Spool Option for Tilting upto 20 Deg.

- pH Probe Adapter

- Thermowell with Tantalum Plug

FAQs of Fluoropolymer And PTFE Lined Closed Dip Pipe:

Q: What is the material used to make this product?

A: The Fluoropolymer and PTFE Lined Closed Dip Pipe is made of high-quality materials such as fluoropolymer and PTFE, which make it resistant to chemical reactions and high temperatures.Q: What is the color of the pipe?

A: The pipe is coated with a white surface treatment that not only looks great but also provides a layer of protection against corrosion and wear and tear.Q: What is the shape of the pipe?

A: The pipe is round in shape, which ensures that it is easy to install and maintain.Q: What is the warranty period for this product?

A: The product comes with a warranty of 18 months, which ensures that you can use it for a long time without any worries.Q: What is the manufacturing process used to make this product?

A: The Fluoropolymer and PTFE Lined Closed Dip Pipe is manufactured using the casting process, which ensures that the product is of the highest quality and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry